Sustainable Manufacturing: 5 Green Tech Processes Reducing Costs by 20% in 2025

As industries worldwide grapple with rising operational costs and urgent environmental mandates, a groundbreaking shift towards Sustainable Manufacturing: 5 Green Tech Processes Reducing Costs by 20% in 2025 (FINANCIAL IMPACT, PRACTICAL SOLUTIONS) is actively underway. This development is not merely a trend but a strategic imperative, promising substantial financial benefits alongside ecological responsibility.

The Urgent Shift to Sustainable Manufacturing

The manufacturing sector is currently experiencing an unprecedented transformation, driven by both economic pressures and increasing regulatory demands for environmental protection. This urgent shift underscores the critical need for adopting sustainable practices that not only reduce ecological footprints but also bolster financial resilience. Companies are realizing that ‘green’ is no longer just about compliance but about competitive advantage.

Recent reports from the World Economic Forum indicate that industries failing to adapt sustainable practices risk significant market share erosion and increased operational expenditures. The push for green tech integration is therefore a direct response to these dynamics, aiming to create more efficient, less wasteful, and ultimately more profitable production cycles. This transition impacts every facet of the supply chain, from raw material sourcing to end-of-life product management.

Advanced Energy Management Systems: Powering Savings

One of the most impactful advancements in sustainable manufacturing is the widespread adoption of Advanced Energy Management Systems (AEMS). These sophisticated platforms are now providing real-time data and actionable insights into energy consumption, allowing manufacturers to optimize usage and drastically cut utility bills. As of early 2024, leading industrial firms are reporting initial savings of 5-10% within the first year of AEMS implementation.

Real-time Monitoring and Optimization

AEMS leverage AI and machine learning to predict energy demand, identify inefficiencies, and automate adjustments across factory operations. This proactive approach minimizes waste and ensures that energy is utilized precisely when and where it is needed, avoiding costly peaks.

- Predictive analytics for energy demand forecasting.

- Automated control of machinery based on production schedules.

- Identification of energy-intensive processes for optimization.

- Integration with renewable energy sources for seamless supply.

Beyond immediate cost savings, the data collected by AEMS provides a comprehensive overview of a company’s energy profile, enabling long-term strategic planning for further reductions and a pathway to carbon neutrality. This granular control over energy consumption is a cornerstone of achieving the projected 20% cost reduction by 2025.

Circular Economy Principles: Waste as a Resource

Embracing circular economy principles is rapidly becoming a cornerstone of sustainable manufacturing, redefining waste not as a byproduct but as a valuable resource. This paradigm shift involves designing products for longevity, reusability, and recyclability, thereby minimizing virgin material consumption and landfill waste. Companies adopting these principles are seeing significant material cost reductions and new revenue streams from recycled content.

The latest industry data from the Ellen MacArthur Foundation highlights that businesses implementing circular models can reduce material input costs by up to 15% while also enhancing brand reputation. This approach requires a complete rethinking of product lifecycle management, from initial design to end-of-life processing. It’s about closing the loop and preventing materials from ever becoming waste.

Design for Disassembly and Recycling

Manufacturers are now focusing on designing products that can be easily disassembled, allowing components to be repaired, reused, or recycled efficiently. This upfront design consideration dramatically simplifies end-of-life processing and reduces the need for new raw materials.

- Modular product designs for easy component replacement.

- Use of mono-materials for simplified recycling streams.

- Take-back programs for end-of-life products.

- Collaboration with recyclers to develop high-quality secondary materials.

By integrating these principles, companies are not only reducing their environmental impact but also unlocking new economic opportunities, proving that sustainability and profitability can go hand-in-hand. This strategy is critical for achieving the ambitious cost reduction targets set for 2025.

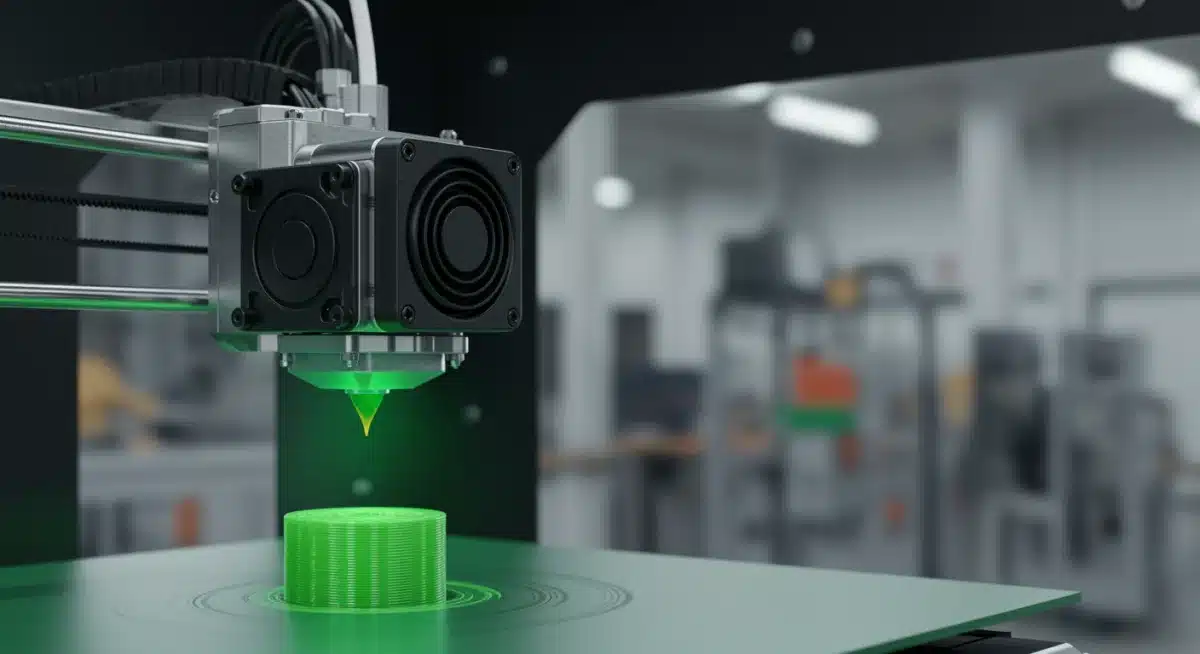

Additive Manufacturing (3D Printing) with Sustainable Materials

Additive Manufacturing, commonly known as 3D printing, is transforming production processes by enabling on-demand creation and significantly reducing material waste. When combined with the use of sustainable and recycled materials, this technology offers a powerful dual advantage: lower material consumption and reduced energy use due to optimized designs and localized production. Recent advancements in bioplastics and recycled metal powders are making 3D printing an increasingly green option.

Analysts project that the global market for sustainable 3D printing materials will grow exponentially, driven by industrial demand for more efficient and eco-friendly production methods. This technology minimizes transportation costs and lead times by allowing production closer to the point of consumption, further contributing to overall cost savings and a reduced carbon footprint.

Localized Production and Waste Minimization

3D printing allows for the creation of complex geometries with minimal material waste, as parts are built layer by layer. This contrasts sharply with traditional subtractive manufacturing, which often generates significant scrap. Furthermore, the ability to print on demand reduces inventory holding costs and the risk of obsolescence.

- Reduced material waste through precise additive processes.

- On-demand production minimizes inventory and storage costs.

- Decentralized manufacturing capabilities reduce shipping emissions.

- Use of innovative sustainable filaments like biomaterials and recycled plastics.

The financial implications are substantial, with companies reporting up to 15% savings on material costs alone, alongside gains in production flexibility and speed to market. This innovative approach is a key driver in the pursuit of Green Tech Manufacturing Savings by 2025.

Industrial Internet of Things (IIoT) for Efficiency

The Industrial Internet of Things (IIoT) is fundamentally reshaping manufacturing operations by connecting machines, sensors, and systems across the factory floor. This interconnected network generates vast amounts of data, which, when analyzed, provides unparalleled insights into process optimization, predictive maintenance, and resource allocation. The result is a significant reduction in downtime, increased operational efficiency, and lower overall costs.

As of late 2023, early adopters of comprehensive IIoT solutions are reporting a 10-15% improvement in equipment uptime and a noticeable decrease in energy consumption due to optimized machine performance. This technology is crucial for achieving the ambitious 20% cost reduction target in sustainable manufacturing by 2025, as it enables a level of precision and control previously unattainable.

Predictive Maintenance and Resource Optimization

IIoT sensors continuously monitor machine health, allowing for predictive maintenance rather than reactive repairs. This prevents costly breakdowns and extends equipment lifespan. Furthermore, IIoT platforms optimize resource usage, from energy to raw materials, ensuring that every input is used efficiently.

- Real-time monitoring of equipment performance and health.

- Predictive analytics to anticipate and prevent machine failures.

- Automated adjustment of production parameters for efficiency.

- Optimized allocation of raw materials and energy resources.

The integration of IIoT creates a smarter, more responsive manufacturing environment, directly contributing to both environmental sustainability and financial performance. It’s an essential component for any firm aiming for significant cost reductions and enhanced eco-efficiency.

Carbon Capture and Utilization (CCU) Technologies

Carbon Capture and Utilization (CCU) technologies represent a frontier in sustainable manufacturing, actively working to mitigate industrial emissions by capturing CO2 and transforming it into valuable products. While still in earlier stages of widespread adoption compared to other green tech processes, the potential for both environmental impact and economic gain is immense. Breakthroughs in catalyst development and energy-efficient capture methods are accelerating its viability.

Pilot projects and early commercial deployments are demonstrating that captured CO2 can be used in diverse applications, from producing fuels and chemicals to creating building materials. This not only reduces greenhouse gas emissions but also generates new revenue streams, offering a dual benefit that aligns perfectly with the goals of sustainable manufacturing. The financial incentives for CCU are growing, including potential carbon credits and market demand for carbon-negative products.

Transforming Emissions into Value

CCU technologies capture carbon dioxide directly from industrial exhaust streams, preventing its release into the atmosphere. This captured CO2 is then processed and converted into useful substances, effectively turning a waste product into a valuable input for other industries.

- Conversion of captured CO2 into synthetic fuels.

- Production of chemicals like methanol and polymers from CO2.

- Incorporation of CO2 into building materials like concrete.

- Potential for carbon credit generation and new market opportunities.

While initial investment can be substantial, the long-term benefits of CCU, including revenue generation from byproduct sales and enhanced environmental compliance, position it as a critical technology for achieving significant cost reductions and sustainability targets by 2025. It represents a bold step towards a truly circular industrial ecosystem.

| Key Green Tech | Primary Cost Reduction Mechanism |

|---|---|

| Advanced Energy Management Systems | Optimizes energy consumption, reduces utility bills via real-time data and AI. |

| Circular Economy Principles | Minimizes virgin material use, creates new revenue from recycled inputs, reduces waste. |

| Additive Manufacturing (3D Printing) | Reduces material waste and transportation costs through on-demand, localized production. |

| Industrial Internet of Things (IIoT) | Enhances operational efficiency, minimizes downtime with predictive maintenance and resource optimization. |

Frequently Asked Questions About Sustainable Manufacturing Costs

Green technologies reduce costs primarily by optimizing resource use (energy, materials, water), minimizing waste generation, improving operational efficiency through automation and data analytics, and sometimes by creating new revenue streams from recycled or repurposed materials. This leads to lower utility bills, reduced raw material expenses, and fewer waste disposal costs.

It is projected that by implementing these five green tech processes, manufacturers can achieve cost reductions of up to 20% by 2025. This significant financial impact stems from a combination of factors including enhanced energy efficiency, circular economy models, reduced material waste, optimized production through IIoT, and potential new income from carbon utilization.

Yes, while initial investments in green technologies can be substantial, the long-term returns often outweigh the upfront costs. Payback periods are increasingly shorter due to rising energy prices, material scarcity, and growing consumer demand for sustainable products. Additionally, government incentives and carbon credit markets further enhance the financial viability of these investments.

The Circular Economy reduces manufacturing costs by minimizing the need for virgin raw materials through recycling, reusing, and repairing components. It also decreases waste disposal fees and can open new markets for products made from recycled content. Designing for longevity and easy disassembly further extends product life and reduces replacement costs.

AI plays a crucial role by powering Advanced Energy Management Systems (AEMS) and Industrial Internet of Things (IIoT) platforms. AI algorithms analyze vast datasets to optimize energy consumption, predict equipment failures for proactive maintenance, and refine production processes to minimize waste and maximize efficiency, directly contributing to significant cost reductions.

Looking Ahead: The Future of Green Manufacturing

The rapid integration of these five green technologies signals a pivotal moment for the manufacturing sector. As industries continue to face economic headwinds and stringent environmental regulations, the adoption of sustainable manufacturing practices will cease to be an option and become a fundamental requirement for survival and growth. What we are witnessing is not just an incremental improvement, but a systemic overhaul that promises not only ecological benefits but also substantial financial returns for proactive companies. Expect to see continued innovation in material science, AI-driven optimization, and circular economy models as the blueprint for industrial success in the coming years. The race to achieve a 20% cost reduction by 2025 is now fully underway, with significant implications for global supply chains and economic resilience.